I. Overview

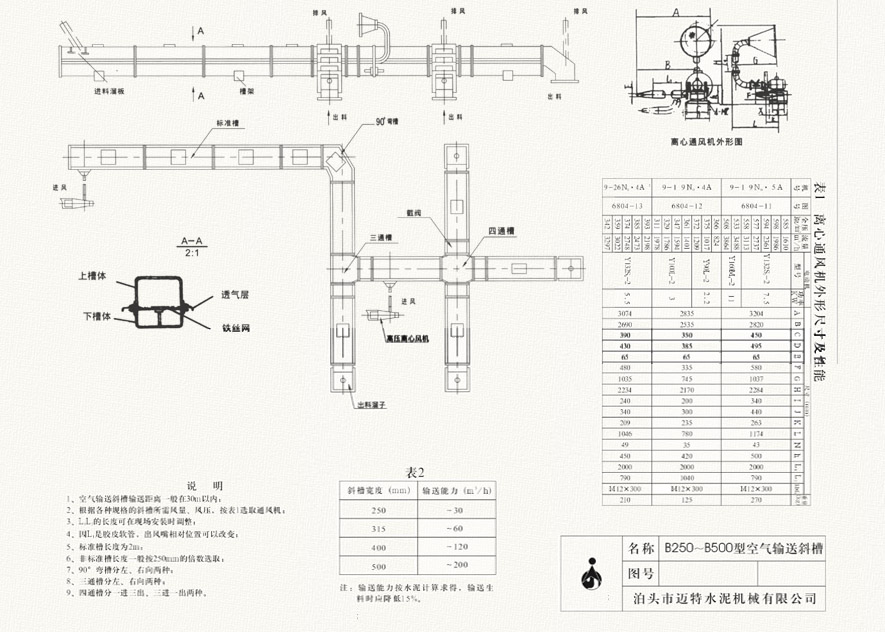

Air

transport chute (hereinafter referred to as the chute) is widely used

in conveying dry powdery material pneumatic conveying equipment in the

cement industry is often used to transport cement and raw meal, chute is

made of a number of ordinary thin steel plate system Into the slot and

other accessories with bolted together. The upper and lower shells are

sandwiched with a breathable layer, and the whole of the inclined groove

is inclined at an angle with the horizontal.

The main component of the chute is the breathable layer. The

flexible thick plate type synthetic fiber fabric used in the design of

this series is a new type of breathable layer which has high temperature

resistance (up to 150 ℃), corrosion resistance, wear resistance, low

hygroscopicity, Light weight, smooth surface, long life and other

advantages. Breathable layer without on-site installation, each tank

assembly by the manufacturer, the scene can be docked together, thus

reducing the installation workload, but also to ensure quality.

II. performance

1, conveying materials: dry powder material.

2, the delivery volume:

The

transport volume of the chute is affected by many factors and often

varies greatly. According to the theoretical calculation, comprehensive

reference of domestic and international reference materials and field

investigation, the following values are recommended for reference when

the slope is 6%.