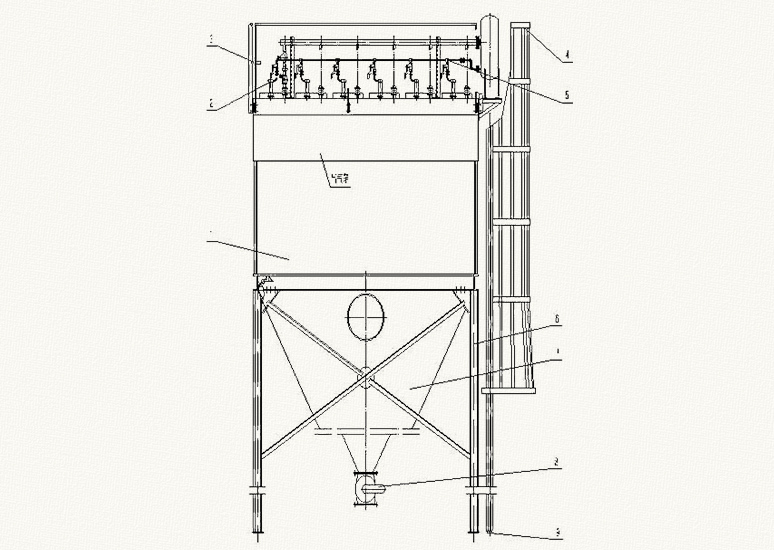

The Basic Structure of PPDC Series Air Box Pulse Bag Dust Collector

1.

Main structure of air bag pulse bag filter The main body consists of

four parts: box, bag room, ash bucket and air inlet. It is equipped with

pillars, ladder, railings, air system, cleaning controller. .

(1) box

The

box is mainly used for fixing the bag filter bag and the air circuit

components, and is made into the totally enclosed form. When the dust is

cleaned, the compressed air enters the box first and half into the

inside of the filter bag. The top of the box made of 1.5 to do the

slope, when used in the outdoors to prevent water, the top also has

access hole repair door, installation and replacement of the bag cage,

filter bag all here, very convenient, according to the different

specifications, And is divided into a number of rooms, each separated by

steel plate, each airtight to achieve off-line (off-line) cleaning,

each room is equipped with a poppet valve to filter off the smoke flow.

(2)

bag room bag room in the lower part of the box, mainly used to

accommodate the bag cage and filter bag, and the formation of a

filtering space, mainly in the purification of flue gas here, with the

same box, according to the different specifications are also divided

into several A room, and separated with partitions to prevent dust in

the room between the mutual interference, while the formation of a

certain settlement space.

(3) hopper

The ash bucket is arranged in the lower part of the baghouse, and it

is used as the intake manifold in addition to the collected dust. When

the dust-laden gas enters the baghouse, it will enter the hopper. As the

hopper bucket has a large volume , So that the air velocity decreases,

coupled with the direction of air flow changes, so that coarse dust

particles here to be separated, ash bucket arranged within the screw

conveyor or air chute and other transportation equipment, exports also

equipped with rotary unloader or turn Plate valve and other lock wind

equipment, continuous ash discharge.

(4) out of the outlet

The

air inlet and outlet are divided into two types according to the

structure of the dust collector. The air inlet of the 32 series is

cylindrical type, welded directly to the side plate of the hopper, and

the lower part of the air box is arranged on the side of the box. And

the inside of the box, and other series of inlet and outlet made of one,

arranged in the side of the bag room, box and hopper between the middle

separated by an oblique partition into the airtight two parts,

respectively, for the inlet and outlet Although the volume of this

structure is bigger, but the air distribution is uniform, the ash bucket

pre-dusting effect is good, suitable for flue gas dust concentration of

large occasions.

1, shell 2, poppet 3, railings 4, ladder 5, compressed air piping system

6, column 7, hopper 8, star feeder 9, the anchor bolts