First, the structure outlined

1,the impeller feeder is the company specifically for raw materials intothe mill, quantitative feeding and as a positive pressure or negativepressure delivery system designed to lock the wind feeding device.

2,the impeller feeder its simple structure, reliable performance, goodsealing performance, there can be replaced and anti-wear lining checkdoor, the structural characteristics of the provisions of the materialinto the mill can not be stuck by the size of the problem. Long-term useat home and abroad highlights the characteristics of the device -smaller size, easy to promote use.

3,the structure of the impeller feeder, including a rotating impeller, afixed shell and drive devices, impeller blades are mostly welded withanti-wear plate to improve the service life of the impeller; feedingcenter distance and the shell centerline A certain deviation is intendedto apply to the entry of larger particles of material. Shell liner isequipped with anti-wear layer; Impeller is supported by both ends of thebearing, the impeller and the shell can guarantee the gap between theuniform; due to the higher feed temperature, leaves and leaves the gapbetween the shell. Sealing at both ends is sealed with asbestos packing,the way is simple, good sealing, easy to operate and replace.

Thisunloader is equipped with hot air channel, when the feed humidity, theimpeller may be a certain thickness of the end of the sticky powdermaterial, then you should pass the higher temperature of the gas, sothat the bottom of the material dry, Then in the bottom of the impellerwill not affect the feed volume, when not in and out of the outletblindly.

Φ1800mmabove the feeder on the side of the shell to open one or two openinspection doors, if necessary, may open, check the internal situationand replace the surface of the anti-wear layer, and the impeller on theanti-wear layer. And there are inspection holes, usually when the debrisinto the impeller or blocking material and other accidents affect thefeeder normal operation, you can open the door for cleaning, or observethe specific circumstances, you can observe the feed situation, thedevice bucket Capacity is generally between 30-50%, not too much intothe material, feed conditions and through the rotation speed of theimpeller to control the device. The faster the feed rate of each bucketless, the slower the feed rate of each bucket the more control can notbe greater than 30-50%, bucket into the feed more than 50% of the easystuck, making the drive damaged.

Notethat the direction of rotation of the impeller to be marked in thedirection of rotation can not be the opposite direction to feed,otherwise there will be stuck phenomenon, impeller overload or impellerabnormalities need to be installed by the demand side of the motorprotection device (overload protection) A proximity switch, through theimpeller rotation signal, the operation of the impeller feeder tomonitor.

Second, technical performance

Atpresent, we design the raw material feed mill three size files,according to the need to design: MT600, MT800, MT1000, MT1200, MT1400,MT1600, MT1800, MT2000, feeding capacity from 80t / h-650 T / h, thenumber of revolutions from 0-27 r / min, are used torque force, smallsize of the frequency control reducer.

Atthe beginning of feeding, be sure to start from the middle speed to thematerial, the number of revolutions too fast, bucket capacity can notreach 30%, the feed is not enough; turn too slowly, fighting capacitywill be filled with the phenomenon of stuck. Grasp the specificsituation to find an objective speed, so as to achieve their own needsto feed. For example: the number of revolutions is 9 r / min, then thefeed start of the number of revolutions from 5 - 7 r / min, schedulingto the corresponding feed rate, not from the slowest start.

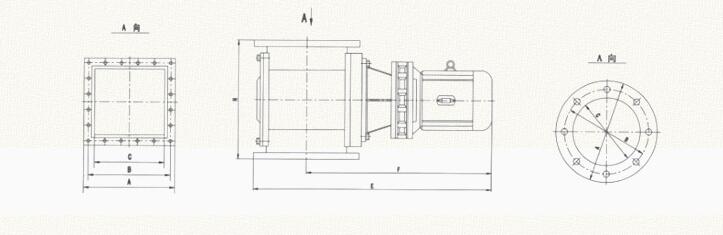

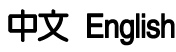

Third, the simplified diagram and selection

Star feeder

I. Overview:

Thisfeeder also known as style wheel, rotary feeder, wheel feeder, summed upbefore the use of the product in the advantages and disadvantages,redesigned and used.

Second, features:

(1) inspection hole increases, so that maintenance and handling a lot of easy to block ash.

(2) reduce the slope of imports, reducing the phenomenon of blocking ash.

(3) in the seal also made a corresponding treatment.

The samewith all cast iron processing, wear resistance increased. Widely usedin building materials, chemical industry, metallurgy, electric power andother industries.

Main technical performance

Model number | Rated output(M/h) | Number of revolutions(r/min) | Matching reducer |

φ 300 | 20 | 31.9 | XLD1. 1-4-47 |

Φ 400 | 56 | 25.4 | XLD2. 2-4-59 |

φ 500 | 68 | 20 | XLD5 5-5-71 |

Dimension Table of Star Feeder

Model number | A | B | C | h | M | H | F | E | Hole diameter |

φ300 | 410 | 360 | 300 | 20 | 225 | 450 | 903 | 1247 | 12一φ18.5 |

φ400 | 560 | 500 | 400 | 20 | 280 | 560 | 1075 | 1478 | 12一φ22 |

φ500 | 660 | 600 | 500 | 20 | 330 | 660 | 1125 | 1578 | 12一φ22 |

model | Per revolution | motor model |

| Operating temperature | Install the junction dimensions |

Power KW | (R / min) | (℃) | A | B | c | M | H | F | E | 8 hole diameter |

2型 | 2Liters / turn | Y801-4/0.55 | 24 | ≤300 | 240 | 200 | 150 | 120 | 240 | 190 | ~680 | 8-09 |

4型 | 4Liters / turn | Y801-4/0.55 | 24 | ≤300 | 280 | 240 | 180 | 140 | 280 | 210 | ~720 | 8-011 |

6型 | 6Liters / turn | Y802-4/0. 75 | 24 | ≤300 | 300 | 260 | 200 | 150 | 300 | 220 | ~740 | 8-011 |

8型 | 8Liters / turn | Y802-4/0. 75 | 24 | ≤300 | 320 | 280 | 220 | 160 | 320 | 230 | ~760 | 8-011 |

10型 | 10Liters / turn | Y90S-4/1 1 | 24 | ≤300 | 340 | 300 | 240 | 170 | 340 | 250 | ~800 | 8-0 13 |

12型 | 12Liters / turn | Y90S-4/1 1 | 24 | ≤300 | 360 | 320 | 260 | 180 | 360 | 260 | ~820 | 8-0 13 |

14型 | 14Liters / turn | Y90S-4/1 1 | 24 | ≤300 | 380 | 340 | 280 | 190 | 380 | 350 | ~1020 | 8-0 17 |

16型 | 16Liters / turn | Y90S-4/1 1 | 24 | ≤300 | 400 | 360 | 300 | 200 | 400 | 360 | ~1040 | 8-0 17 |

18型 | 18Liters / turn | Y90L-4/1 5 | 24 | ≤300 | 420 | 380 | 320 | 210 | 420 | 370 | ~1080 | 8-0 17 |

20型 | 20Liters / turn | Y90L-4/1 5 | 24 | ≤300 | 440 | 400 | 340 | 220 | 440 | 380 | ~1100 | 8-0 17 |

26型 | 26Liters / turn | Y100L-4/2.2 | 24 | ≤300 | 500 | 460 | 400 | 250 | 500 | 410 | ~1200 | 8-0 17 |

30型 | 30Liters / turn | Y100L-4/2.2 | 24 | ≤300 | 540 | 500 | 440 | 270 | 540 | 430 | ~1240 | 8-0 17 |

36型 | 36Liters / turn | Y100L-4/4 | 24 | ≤300 | 600 | 560 | 500 | 300 | 600 | 460 | ~1280 | 8-020 |

40型 | 40Liters / turn | Y100L-4/4 | 24 | ≤300 | 640 | 600 | 540 | 320 | 640 | 480 | ~1380 | 8-020 |