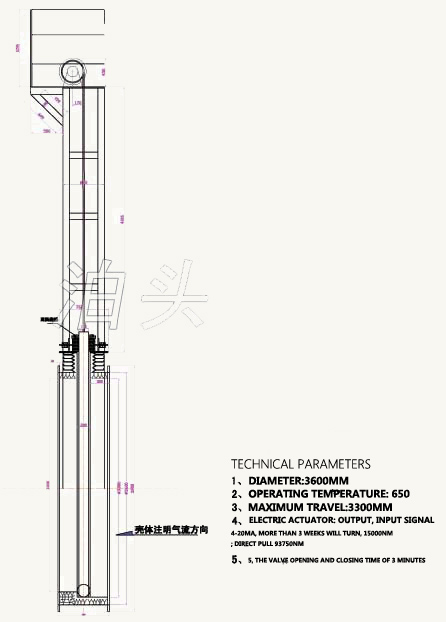

To

ensure the life of high-temperature flapper valve concrete measures in

the final analysis is: structure - materials - process - to ensure a

four-step process of grasp

1,

the kiln system in normal working condition, the airflow is not very

stable, causing the valve plate shaking, collision. Remedy: Install the

tracking seal of the valve plate; when the valve plate is inserted

Deviated from the center line 20mm, easy to reduce the valve plate

leakage and vibration; valve plate with wind chute, reducing wear and

tear, conducive to sealing.

2,

to reduce the harmful substances in the hot air erosion, increase

temperature, anti-erosion. Measures: reduce the metal exposed in the

valve surface to increase the protective layer of castable; select the

tertiary air

Tube valve plate material for ultra-fine high-purity mullite and a small amount of corundum based castable.

3,

the overall structure of the valve plate design is very important.

Valve plate material and structure: the valve plate with 0Cr25Ni20Si2

heat-resistant steel welded into a network structure; according to the

metal and castable

Thermal expansion coefficient, determine the thickness of spray

materials, reasonable arrangements for the density of palladium nails

and castable protective layer thickness.

4, pouring site and the casting plant is different

1) the size of the various parts of the valve can not be grasped in

the field casting, because our company can accurately cast the size of

each part of the valve with the model,

When the valve plate due to thermal expansion can not afford to die, off the case of death.

2) pouring can not grasp the castable material to join the water

(especially the valve body), the scene requires a good castable

fluidity, so adding water must exceed the standard,

Too much water caused by loose material after casting, hardness

decreases, so intolerant erosion. Water caused by excessive physical

water increases, the crystallization of water to reach a certain

temperature after the volatile

Destroying the structure between the castable, resulting in valve

body affect the quality of soft body. Within the company can be strictly

controlled water pouring and mixing time, transport distance (usually a

dozen seconds to transport in place). Cast mold control when the

factory properly, the body of the physical moisture has sufficient time

to volatilize.

5,

sealing control: the shell has a sliding plate inside the valve plate,

when the valve plate is closed by the wind pressure, the valve plate and

shell contact surface tightness increases, the valve does not leak

The role of wind. External with a tracking seal, play a positive

pressure when the hot air does not overflow, negative pressure does not

enter the role of air conditioning

6,

the force control: I selected the company's gate valve selection drive a

larger torque, lifting force to reach more than 8 tons, not only to

overcome the weight of the valve plate itself, but also overcome

Friction caused by wind pressure. Coefficients are selected in more than 1.5.

Contrast of high - temperature flapper valve driven traction

First, the drawback of the traditional traction device:

Reducer

wire rope drum or reducer chain drive are soft connection drive, close

the valve plate in case of accidental stuck or pipe fouling drive can

not get feedback,

Thereby continuing to cause the signal transmission error, reverse movement, damage to equipment and other hazards.

I use the company rack and pinion traction device

First

of all, encountered a valve plate accidentally jammed in addition to

the weight of the valve plate and produce more than 1.5 plate gravity

equivalent to the thrust of 2.5 times the valve plate gravity to promote

the valve plate, making the valve plate can Shun

Lee

closed. Second, when the pipe fouling serious, the valve plate is not

in place, the actuator starts over torque protection. The design is

rugged and durable, while avoiding traditional traction

The serious consequences of the home.

Second, the drive:

Traditional high temperature valve reducer + roller + displacement sensor drive mode, the drawback is

1, the drive traction for the soft connection, can not correctly locate the valve plate position;

2, displacement sensors are mostly resistive, low sensitivity, short service life;

3, can only provide the output signal, not two-way control, operation trouble.

I

use the brake with a multi-turn large torque actuator, precise

positioning valve plate position, input and output 4-20mA, through the

control room control, controllable operation, operation

For convenience.

Third, why the factory to lay a good castable?

1, castable casting pouring foam type, to ensure the accuracy of the various parts of the size.

2,

the company playing poured material can be a good control of water,

making the valve part of the casting is not loose, do not fall off,

anti-erosion, high wear resistance.

3,

because the valve casting materials and valves are manufactured by the

Company completed, will not appear because the valve does not close, not

open the phenomenon of shirking responsibility. Valve if there are all

problems

By the Company.